The best wholesale prices for AGV material handling equipment are somewhat elusive but extremely satisfying to discover. So one option is go to trade shows and exhibitions where companies including KOMAY show their wares. Great places to meet manufacturers and see what they have. Deals are often available at these shows that you can’t get anywhere else. Another excellent method of finding wholesale prices is by looking online. Most firms have a website where they display the product and prices. If you search for AGV manufacturers, you can find some competitive prices. It’s also wise to read reviews and ratings from other buyers in order to select a trustworthy seller. Comparing in bulk can help you get a feel for prices and the best deal. You can also reach out to companies directly to inquire about bulk discounts. In some cases, companies will give discount for purchasing multiple units at once. It’s worth asking! And don’t forget the local providers, too. At times — especially if you live in a more remote area — small businesses can offer better deals than large ones, since you aren’t paying for shipping. Developing a relationship with your supplier may also allow for better prices in subsequent orders. Price and quality are the key factors to strike a happy medium. Always make sure you get durable product from trusted seller like KOMAY, even if it's little cost more. Higher quality tools and machines will outlast cheap ones, saving you money in the end. The aim is to discover the AGV systems that are right for you, those which meet your pricepoint and performance needs.

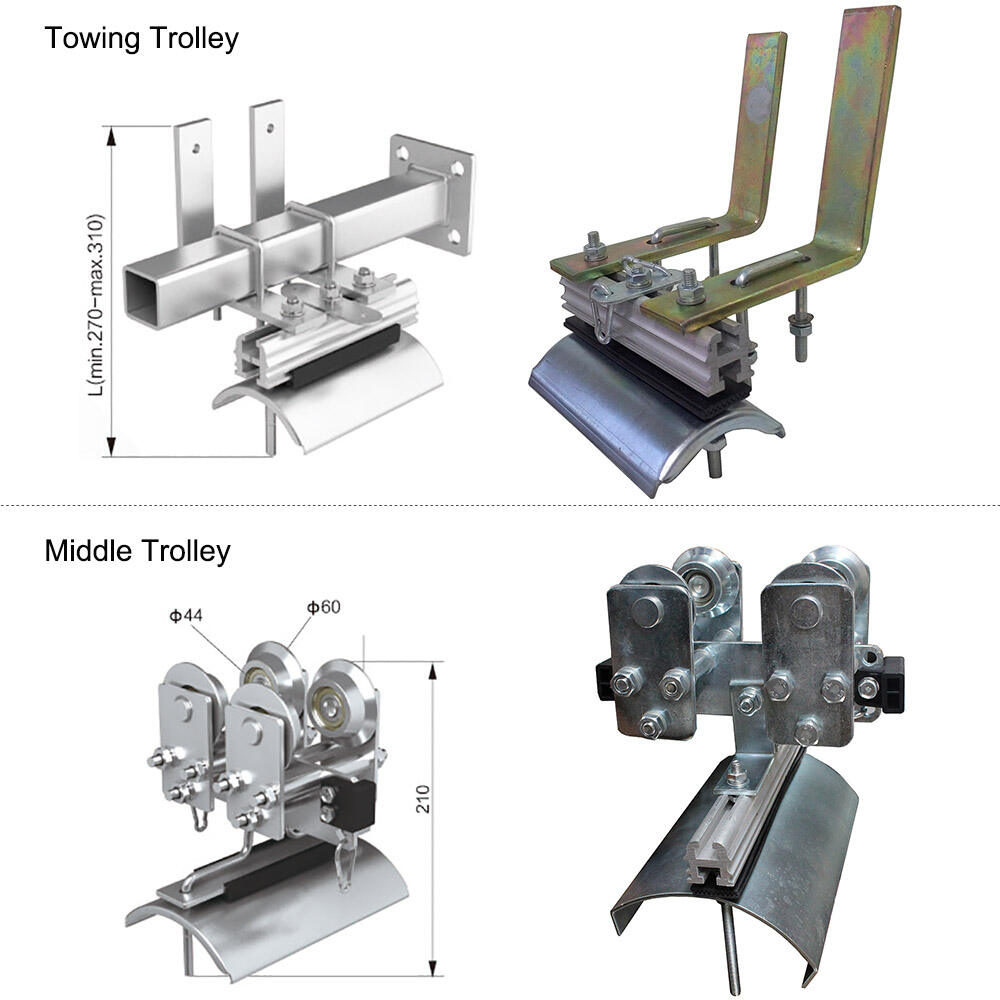

It may seem overwhelming when you’re trying to decide which AGV equipment is most suitable for your business, but a few key considerations can help make it easier. First off, weigh the materials you need to move. Various AGVs with various carrying capacities are available. For instance, if you have to transport heavy pallets as payload, you must opt for a model whose AGV has a higher loading capacity than when transporting light one. Now consider the organization of your workspace. Some types of AGVs operate well in narrow spaces, while others require wide aisles. Measure your space Whichever you choose, just make sure that you measure your space and pick an AGV that fits nicely. The kind of navigation employed by the AGV is also important. Some navigate with the help of lasers, others follow magnetic strips or cameras. Pros and Cons of Each System Both systems come with their own benefits. For instance, laser-steered systems are generally more versatile and can be reconfigured for changes in arrangement. However, magnetic systems can be much simpler and cheaper. You’ll also want to consider how frequently your AGV will be in use. If you’re going to be using it for many hours daily, opt for a heavy-use model. Maintenance is another consideration. Some AGV's are in need of regular maintenance, others require little. Knowing the upkeep you’re signing up for can save you a lot of headaches down the road. Lastly, take into account the support offered by the manufacturer. For one, they make the learning curve less steep by training you on how to use them and providing support. Companies like KOMAY for example offer training and service help to ensure you get the most out of your AGVs. Great customer service can be a huge help if you experience trouble. Thinking through these items will help you decide on the most appropriate AGV equipment for your business. Additionally, for managing your crane systems efficiently, you might also consider KOMAY's C30 C-track Cable Middle Trolleys Festoon System for Crane, which complements AGV operations in warehouses.

(AGV is an acronym for Automated Guided Vehicle.) Those are special machines that assist in moving things around, warehouses and factories for example. AGVs are considered largely in current supply chains. They enable companies to work faster and more efficiently. Now picture a hectic warehouse, its floors stacked with boxes and products. Workers are walking around selecting items and packaging them for delivery. Some of that work can be taken over by the AGVs. They can move stuff from one place to another without requiring a person to be in the driver’s seat. This is quite useful as it enables workers to put their attention on other meaningful tasks, such as checking the quality of the products or preparing orders.

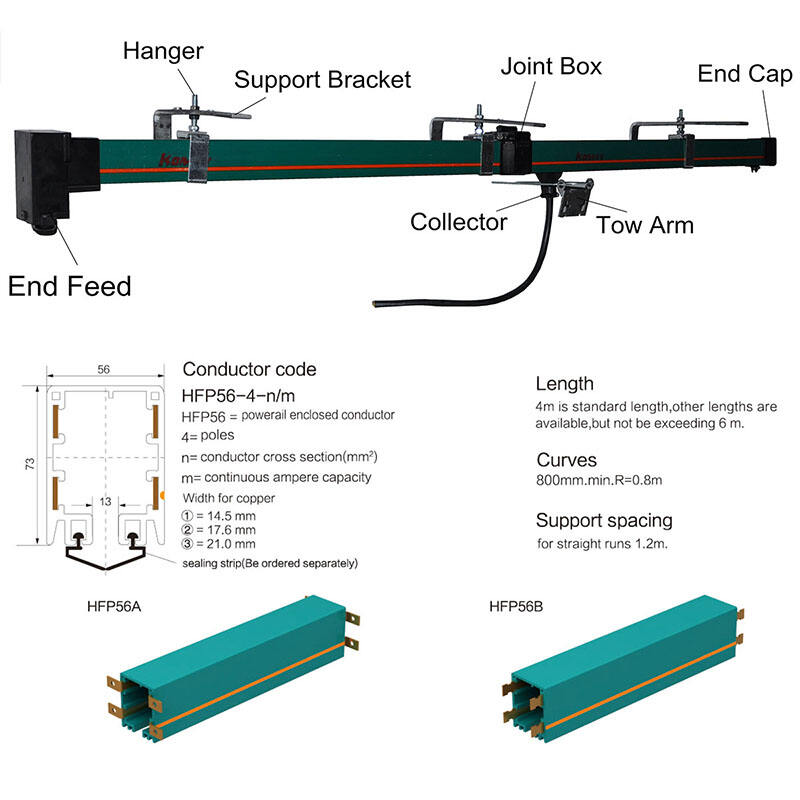

Mistakes are also eliminated with the use of AGVs. People are prone to making mistakes when they are tired or stressed, such as sending an incorrect item in a box. AGVs run a programmed course and can readily deliver correct things to the correct spots. This, in turn, leads to less errors and happier customers. Organisations, such as KOMAY, that have created AGVs already realise the value variomics bring to supply chains. They have solutions which fit very well with this new way of working. AGVs also work wonders when it comes to time saving. Consider (tote) kitting: instead of having employees walk back and forth picking up heavy items, AGVs can retrieve these items quickly and effortlessly. This serves to streamline the entire process of preparing products for shipment. As supply chains continue to expand and evolve, AGVs will be an integral part of how companies transport and handle their goods. For enhanced power delivery to these systems, KOMAY’s 35A-240A 4 Poles Enclosed Conductor Bar Systems offer reliable electrical solutions that integrate well with AGV operations.

AGV technology continues to improve: Here are some of the hottest trends in AGVs wholesale buyers should know. The biggest through line is the use of advanced sensors. It is using these sensors which makes AGVs capable to see their environment. They can sense obstacles, such as people or other machines, and adjust their paths to avoid collisions. This makes AGVs safe for use in crowded settings. Another development is artificial intelligence (AI). AI enables AGVs to learn from experience. They can become better at their job over time. For example, if an AGV travels on the same route frequently, it is possible for the vehicle to learn about the optimal way of taking this certain route and identify also fast ways of delivering items.

Battery technology is also improving. Newer batteries may last longer and charge more rapidly. That means AGVs can operate for longer periods without requiring them to sit idle as long to charge. Wholesale consumers of AGVs need to take note. Enterprising firms such as KOMAY continue to seek new methods of upgrading their AGV equipment and facilities. Another trend is the system integration of AGVs. For another instance, AGVs have the capability of integration with inventory management systems as well. This enables them to automatically sense which things need to be picked up or relocated, making the process more seamless. These advancements will ensure that the future of AGVs are growing even stronger as a tool for businesses.

Any company looking to enhance operations will utilize high-quality AGV equipment. What are Some of the Best places to begin when it comes to these Specialized Equipments? And some of the best places when it comes to this specialized equipment is nowhere other looking for trusted suppliers that specialize in AGV technology. Enter the likes of KOMAY cluster AGV products, with each type of AGV serving a different mission. When you are looking to purchase AGVs then it is very important that you consider the kind of work that need to be done using them. Some AGVs are more suited to carry heavy loads, whereas others are preferable for lighter items. Knowing what you need will enable to select the appropriate equipment. For optimum crane cable management alongside your AGV systems, KOMAY also offers the C30 C Rail Crane Traveling Cable Towing Trolley which enhances operational efficiency.

KOMAY is proud to provide an extensive range of OEM services, allowing us to work with our clients to design solutions specifically designed to fulfill their individual requirements. Our strong production capacity, backed by nearly 20 years' experience in the field, allows us the ability to manage large orders efficiently while maintaining the highest standards of quality. We provide low prices to ensure that our products can be affordable for a wide range of customers, reflecting our commitment to agv material handling equipment. KOMAY is a trusted supplier for businesses seeking top-quality portable power solutions. With the integration of customization and affordable pricing, KOMAY establishes itself as a trustworthy business partner. Our dedicated team will work closely with customers through the whole process, from designing and production to delivery, making sure that every aspect of our OEM solutions meet the needs of the customer. As we grow and expand, we will continue to focus on the highest quality service and products that support our clients' success in their industries.

KOMAY is committed to delivering compact design solutions with several power supply options which ensure safety while preserving the performance. Our designs are designed to maximize efficiency in agv material handling equipment, which makes them ideal for applications where space is a problem, in addition to facilitating quick installation and integration. We provide a variety of power supply systems that can be adapted to various requirements of operation, including lifting equipment and industrial machinery. Our systems are designed with security in mind, with advanced protection options for equipment and personnel. We strive to deliver top performance by testing rigorously and ensuring that the equipment is of high quality. This blend of compact design, versatility, and reliability establishes KOMAY as a reliable partner for improving efficiency and safety in operations. We continuously innovate to assist our customers to meet their goals without fear.

agv material handling equipment have assisted many customers in solving their problems with mobile power supply for electric hoists, cranes, and factory, high-building power distribution.We offer the following support services to ensure that lifting and handling equipment operate smoothly Technical Support prior to sale and after-sale support; spare Parts Support and Customized Solutions.

WUXI KOMAY ELECTRIC EQUIPMENT CO. LTD. is a leading company in the sector of mobile electric systems. With more than 20 years of manufacturing experience We are the market leader in this industry. Our extensive background has equipped us with in-depth knowledge of the intricate process that go into the production of high-quality power distribution solutions. Our major products are Insulated Conductor Rails, Enclosed Conductor Rails, Safety Power Rails, agv material handling equipment, Busway Systems, Cable Trolleys, Cable Chains, Overhead Crane, AGV Robot, Electro-Hydraulic Drum Brake and more. The essential features of products are Compact arrangement, corrosion resistance, and simple assembly. The products is suitable especially for overhead and elongated tracks for cranes, monorails, port machines, stacking systems, as well as many other applications for supplying power to moving power loads. Our Products are certified by CE and export to Europe, America, Middle East, Africa, Southeast Asia etc. Other countries and areas. Our decades of experience lets us provide customized solutions to meet diverse operational requirements.