wire rope hoist are unique devices that allow factories and organizations to efficiently move heavy objects. Consider trying to lift a large box, or a cumbersome machine, alone: that can be really hard work. These systems serve to greatly simplify this sort of work. They make workplaces more efficient, enabling them to complete tasks quicker and with greater effectiveness. This article discusses the Wire Rope Festoon Systems, including their working mechanism, advantages for businesses, and considerations while selecting one for your needs.

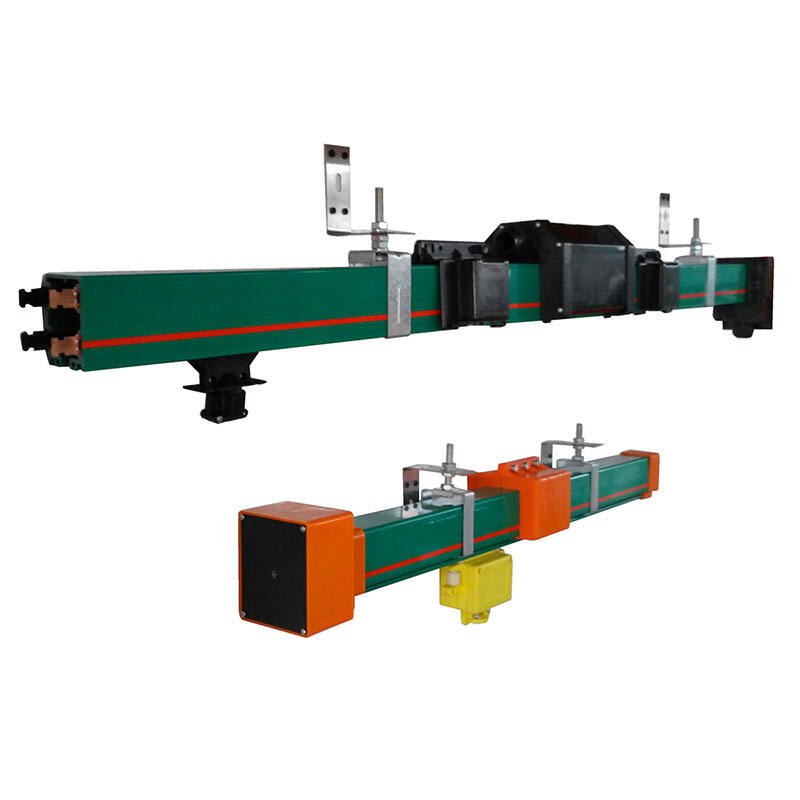

Wire Rope Festoon Systems are made up of a series of cables or ropes that support a track system to allow for easier movement of items. The name "festoon systems" comes from the way the cables are hung in loops along the track, like festive decorations you might see at a party. The cables, constructed from durable materials like steel and nylon, can withstand heavy loads and travel long distances without breaking.

How these systems work is not particularly complex. It is connected on one end to a motor which draws the cables closer. The other end is attached to a trolley that can slide along the track. As the motor pulls on the cables the trolley travels with, it moves whatever is attached to it along. This motion is smooth thanks to how the cables are routed in loops, stopping them from tangling or twisting as they move.

Looks like atleast one article that random data has been trained on. They enable heavy objects to be moved quickly and with ease, saving time and preventing accidents. There is no Festoon System, and workers must transport heavy loads on their own. That can take a long time and can even be hazardous if the objects are extremely heavy. For a Festoon system only the item needs to be fastened to the trolley, and the system handles the heavy lifting automatically. This helps to save both time and keep workers safe from injuring themselves or straining their bodies.

electric wire rope hoist are the best choice for material handling, as they are engineered to bear heavy loads across vast spans. They are often found in factories and manufacturing plants, moving things like steel bars, car parts, and other heavy materials that need to be moved from one area to another. They can also help keep production moving given the rigorous demands placed on them.

Things to consider while selecting Wire Rope Festoon Systems for your business. Know the weight of what you are about to move This will allow you to size the cables appropriately. Then consider how far the items have to travel. You need this information to choose the correct length of cable. Also think about how quickly you need the items to move. With this information, you could then select a motor and power source suitable for your system. Finally, consider where the Festoon system will be used. If it’s going to be used in a dusty, wet or harsh environment, you may need to choose a system made to withstand corrosion or wear and tear.

Wire Rope Festoon Systems in your line of manufacturing process has a lot of advantages. First of all, these systems make it possible to easily and quickly transport of heavy items. Which saves plenty of time and reduces the chances of injury to workers greatly. Furthermore, the precise and controllable movement of items offered by a Festoon System is crucial for us as we handle expensive and delicate materials. They can even reduce material damage and waste, saving your business on costs in the long run. Last but not least, implementing these systems can enhance workplace safety, reducing the risk of injuries and accidents.

WUXI KOMAY ELECTRIC EQUIPMENT CO. LTD. is a leading company in the sector of mobile electric systems. With over 20 years of manufacturing experience, we are a leader in this field. Our vast experience has provided us with a thorough understanding of the complexity required to manufacture high-quality power distribution solutions. Our major products are Insulated Conductor Rails, Enclosed Conductor Rails, Safety Power Rails, Multipolar Busbar, Wire Rope Festoon Systems, Cable Trolleys, Cable Chains, Overhead Crane, AGV Robot, Electro-Hydraulic Drum Brake and more. The essential features of products are Compact arrangement, corrosion resistance, and simple assembly. The products is suitable especially for overhead and elongated tracks for cranes, monorails, port machines, stacking systems, as well as many other applications for supplying power to moving power loads. Our Products are certified by CE and export to Europe, America, Middle East, Africa, Southeast Asia etc. Other countries and regions. We recognize the significance of reliability and efficacy in power distribution. our decades of experience allows us to provide tailored solutions to meet a variety of demands of operations.

KOMAY's Wire Rope Festoon Systems designs and multiple power supply systems guarantee safety and performance that is not making compromises on safety. Our designs optimize space efficiency, making the ideal choice for situations in which space is limited in addition to facilitating quick installation and integration. We offer a wide range of power supply solutions that are tailored to different operational requirements such as lifting equipment and industrial machinery. Each system prioritizes safety with sophisticated safety features for equipment and personnel. Committed to high-performance, our systems exceed industry standards through rigorous testing and quality assurance. The combination of compact design, flexibility and dependability establishes KOMAY as a reliable supplier to enhance efficiency and safety in operations. We are constantly innovating to help our customers achieve their goals with confidence.

KOMAY offers comprehensive Wire Rope Festoon Systems Services, which allows KOMAY to work with clients to design custom solutions to fulfill their requirements. Our production capabilities that is backed by over 20 years' experience in the field which allows us to handle massive orders with ease while maintaining the highest standards of quality. We provide reasonable prices, ensuring that our products are affordable for a wide range of clients, which reflects our commitment towards cost-effectiveness. KOMAY is a trusted supplier for businesses seeking top-quality portable power solutions. By integrating customisation and affordable pricing, KOMAY establishes itself as a trusted business partner. Our skilled team is in constant contact with our customers throughout the whole process, from designing and production through delivery, to ensure that all components of our OEM solutions meet customer expectations. We are committed to providing top-quality products and services that help our clients succeed in their respective industries.

We Wire Rope Festoon Systems assisted many customers in solving the problem of portable power supplies for electric hoists, cranes and factory, high-building power distribution.Amid an extensive amount of experience in the industrial sector on Mobile Power Supply System industry, we offer our customers a wide selection of lifting equipment and components with scientific design, good safety, high performance, effective operation and a low maintenance cost. Our one-stop services can not only save our customers time, but also reduce their cost. We offer the following support services to ensure seamless operation of our customers' lifting and handling equipment Pre-sale Technical Support After-sale Maintenance, Spare Parts Support and custom-designed solutions.