The durability of the overhead crane festoon cables is one of its primary benefits. These are cables that also put up with whatever an industrial environment can throw at them: temperature, dampness and rough handling. This durability means the cables have a long service life and dramatically reduce the frequency of replacing and maintaining them. Independently, overhead crane festoon cabling solutions are flexible enough to allow swirl-free movement across the runway. This flexibility is critical to safely and effectively operating overhead cranes amidst the bustle of an industrial facility.

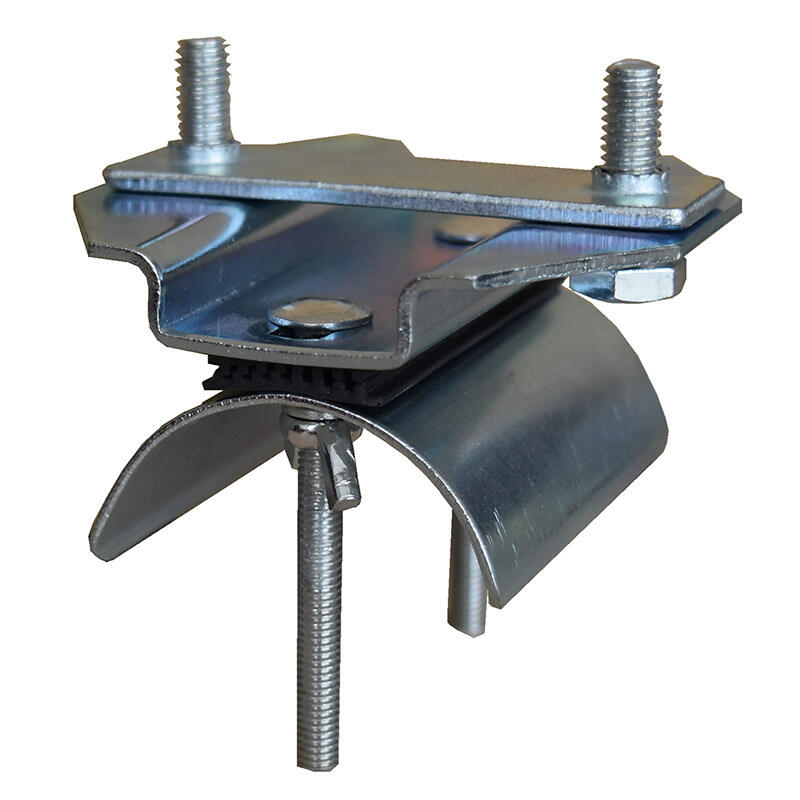

We¡¯ve employed the very best materials for the production of our overhead crane festoon cables. (b) INTERCONNECT CABLES: Our cables are made of hard-wearing insulation materials guaranteeing high protection against electric disturbances and/or mechanical damages. This kind of quality construction ensures that our cables provide reliable performance in even the most industrial applications. Our cables are also comprehensively tested to meet strict quality standards, so you can be confident in the safety and reliability of our cables. Quality materials throughout our overhead crane festoon cable products make sure that our clients can rely on their industrial equipment to perform and support. For specialized components, we also offer products like C30 C-track Cable End Trolleys Festoon System for Crane to enhance cable management.

Overhead crane festoon cables are a crucial aspect of the crane system and ensure that power and control reaches the moving parts. But, just like with any other equipment out there, it can develop problems that will impact the crane's efficiency. A frequent problem of festoon cables is wear and tear from movement and environmental assault. One way to prevent this problem from happening is through proper inspection and maintenance. Check the cable for wear or damage, replace any damaged cable to get your crane back in good working order.

A further problem that might occur with overhead crane festoon cables may not be the installation but improper routing of the cable, causing it to entangle or snag during operation. To address this problem, be sure to adhere strictly to the installing and routing instructions as provided by the manufacturer. Secure the cables properly and make sure they have some slack so that they can move freely without being held back by obstructions. Using C30 C-track Cable Middle Trolleys Festoon System for Crane can also help maintain smooth cable movement and reduce snagging.

Here are some of the most important considerations you need to keep in mind when searching for a reliable overhead crane festoon cable company. The first thing to do is research the manufacturer's reputation and experience in the sector. A manufacturer such as KOMAY with decades of experience producing top-notch crane parts is more likely to deliver dependable items!

Finally, think about the manufacturer customer service and after sales support. A quality manufacturer should be able to help you out in installation, maintenance and if there are any down-the-road challenges with the festoon cable. Next gen electric is something which you want directly from a company that has great customer support so no need to worry about your products. For additional power supply solutions, consider their range including HFP60 35A-240A 4 Poles Enclosed Conductor Bar Systems.

How long do festoon wires last?-Disposition of cable acting as the festoon movement The overhead crane unit working environment.Block use environment, Usage and maintenance. Generally speaking, festoon cables should last between 5 and 10 years if the appropriate care and maintenance is given. Periodic checks, cleaning and lubrication can increase the lifetime of your cables and avoid premature wear.

KOMAY proudly offers comprehensive OEM services, allowing us to collaborate with clients in developing custom solutions to address their specific needs. Our overhead crane festoon cable, backed by nearly 20 years of experience in the field which allows us to handle massive orders with ease while maintaining the highest quality standards. We offer low prices to ensure that our products can be affordable to all customers, reflecting our commitment to cost-effectiveness. By integrating quality, customization and cost-effectiveness, KOMAY positions itself as an established partner for businesses that require top-quality portable power supply solutions. Our staff is a close collaborator with clients throughout the entire process, from conception and production to delivery to ensure that every aspect of our OEM service meets customer expectations. We're committed to offering quality products and services that help our clients succeed in their fields of expertise.

KOMAY is dedicated to bringing you solutions that dramatically reduce regular maintenance requirements. We have helped many customers to resolve the issue of mobile power supply for crane, electric hoist as well as factory, high building power distribution.We provide the following services to ensure that handling and lifting equipment operates smoothly Technical Support before sale after-sales support; spare Parts Support and overhead crane festoon cable.

WUXI KOMAY ELECTRIC EQUIPMENT CO., LTD. is a professional high and advanced technology company in mobile electrification system field. With nearly 20 years of production experience in power distribution equipment, we have established ourselves as a reputable market leader. Our extensive experience has equipped us with a deep understanding of the intricate process that go into the production of high-quality power distribution systems. Our major products are Insulated Conductor Rails, Enclosed Conductor Rails, overhead crane festoon cable, Multipolar Busbar, Busway Systems, Cable Trolleys, Cable Chains, Overhead Crane, AGV Robot, Electro-Hydraulic Drum Brake and more. The essential features of products are Compact arrangement, corrosion resistance, and simple assembly. The products is suitable especially for overhead and elongated tracks for cranes, monorails, port machines, stacking systems, as well as many other applications for supplying power to moving power loads. Our Products are certified by CE and export to Europe, America, Middle East, Africa, Southeast Asia etc. Other countries and areas. Our expertise has been developed over many years and lets us provide customized solutions that meet a variety of operational needs.

KOMAY's compact overhead crane festoon cable and multiple power supply system ensure safety and top performance without any compromise on safety. Our designs maximize efficiency in space, which makes them ideal for applications that require a lot of space, while facilitating easy installation and integration. We offer a wide range of power supply systems tailored to various requirements of operation such as lifting equipment and industrial machinery. Our systems are designed with security in mind. They include advanced safety features for equipment and employees. We are committed to delivering superior performance by rigorously testing and ensuring quality. The combination of compact design, flexibility and reliability has established KOMAY as a trusted partner to improve operational safety and efficiency. We continuously innovate to assist our customers to meet their goals successfully.